Smart Residential Energy Monitoring with Photovoltaic Generation, Battery Storage and Grid Connection

This article provides information on how to connect Deye solar inverter with Shelly Pro MODBUS Add-on over RS485 communication interface.

Introduction

Modern households increasingly rely on renewable energy solutions to reduce expenses, increase energy autonomy, and participate in smart-grid optimization. This project presents a fully integrated solar energy system composed of a Deye inverter, an external battery, solar panels, an electrical distribution box with an ATS (Automatic Transfer Switch), and a Shelly Pro monitoring network featuring the Shelly Pro EM-50 and RS485 Add-on.

The system provides continuous monitoring of energy production, consumption, and storage, enabling informed decisions related to energy cost optimization, self-consumption, and load control. Additionally, by leveraging battery storage and intelligent algorithms, the system can sell energy back to the grid when electricity prices are high and store energy when prices are low.

System Architecture

The core system consists of:

Deye single-phase inverter with PV input, battery storage support

External Li-ion battery bank with JK-BMS 200

PV array of solar panels

ATS-enabled electrical distribution cabinet

Shelly Pro EM-50 energy meter

Shelly Pro RS485 Add-on

Communication wiring (power and data)

This architecture allows seamless energy flow between the PV array, inverter, household loads, battery storage, and the grid. The ATS ensures automatic transfer of power in the event of grid failure, maintaining power continuity.

Hardware Integration

1. Deye Inverter Installation and Configuration

The Deye inverter serves as the central control device. It performs PV energy management using MPPT controler, AC coupling, DC battery management, and grid synchronization. Proper commissioning includes configuring inverter modes (self-consumption, grid sell, time-of-use), setting charge/discharge limits, and defining battery compatibility parameters.

2. Battery System Configuration

The battery pack with JK-BMS200

JK-BMS 200 control panel

The external battery is integrated via CAN/RS485 communication to establish synchronized charging behavior with the inverter. Configuration steps include:

Voltage and current limits

Battery chemistry settings

Charge/discharge timing

Grid export permissions

Correct configuration ensures the battery will store energy when electricity cost is low and discharge when profitable.

3. Solar Panel Integration

Solar panels are wired using appropriate DC cabling, surge protection, and connected to the inverter PV inputs. Sizing considerations include energy demand, seasonal performance, and local regulations.

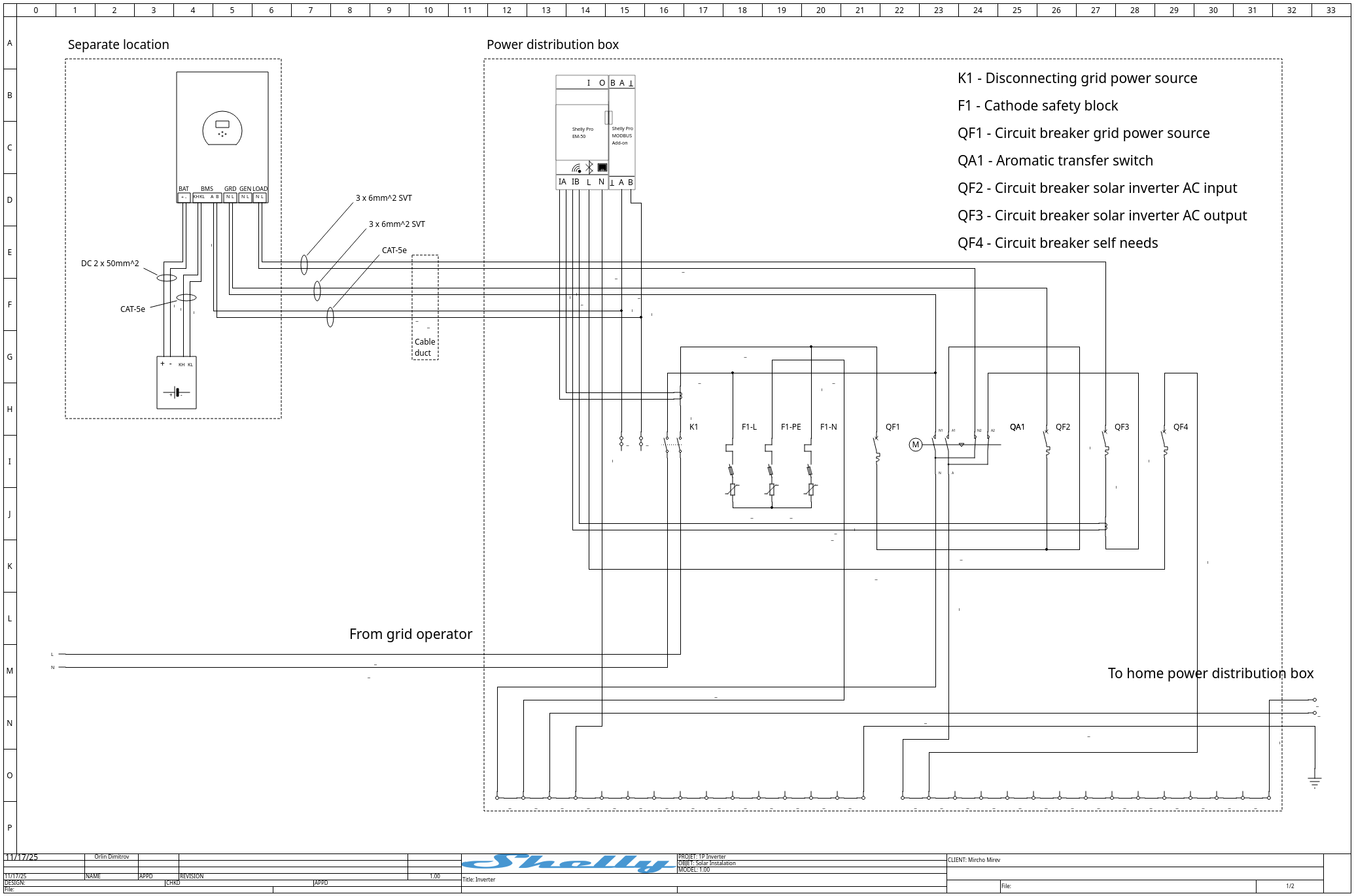

4. Electrical Distribution Cabinet with ATS

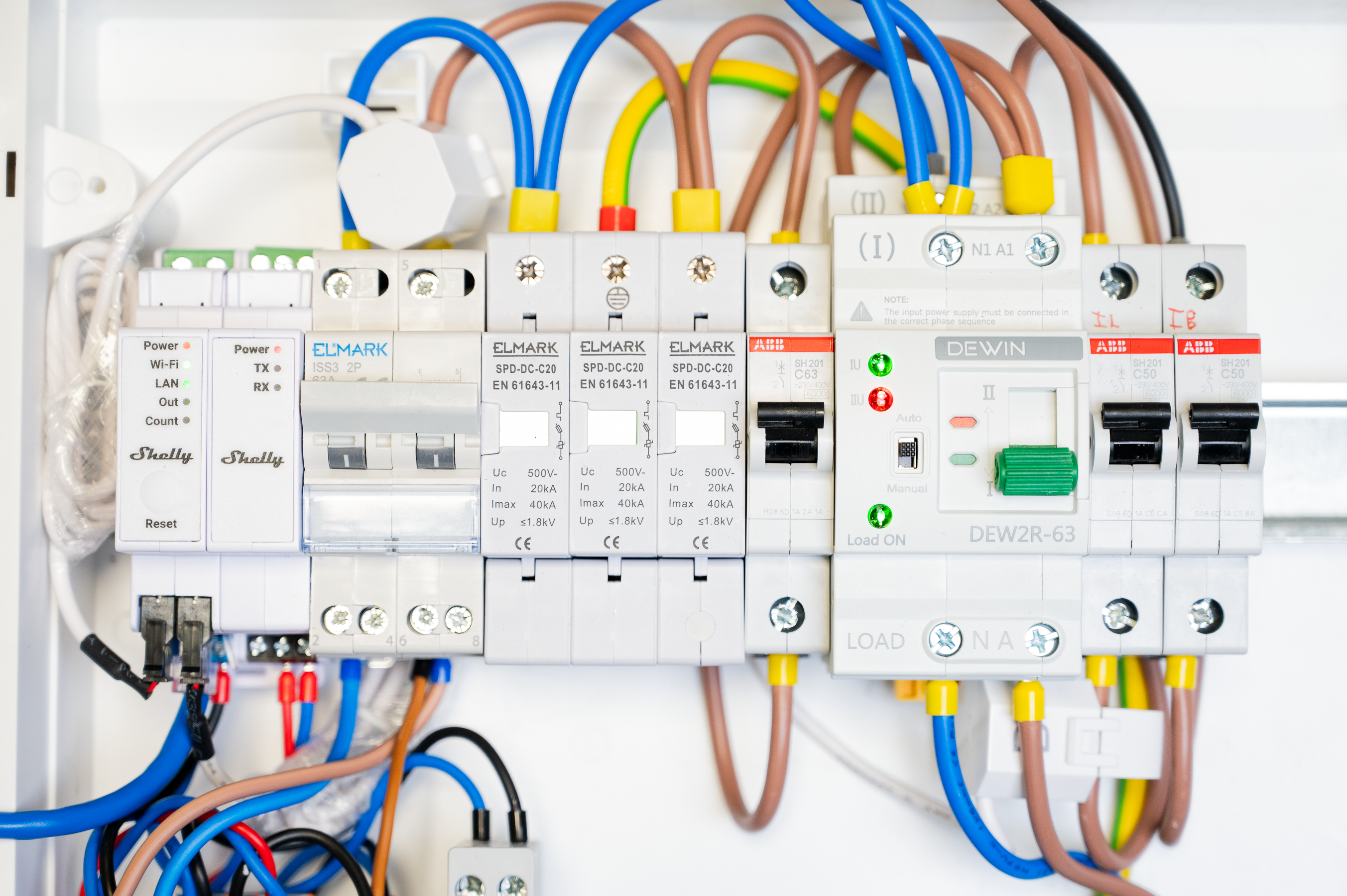

Shelly Pro EM-50, main power switch, cathodic protection, CB for the protection, ATS switch, CB for the input of the inverter, CB for the output of the inverter.

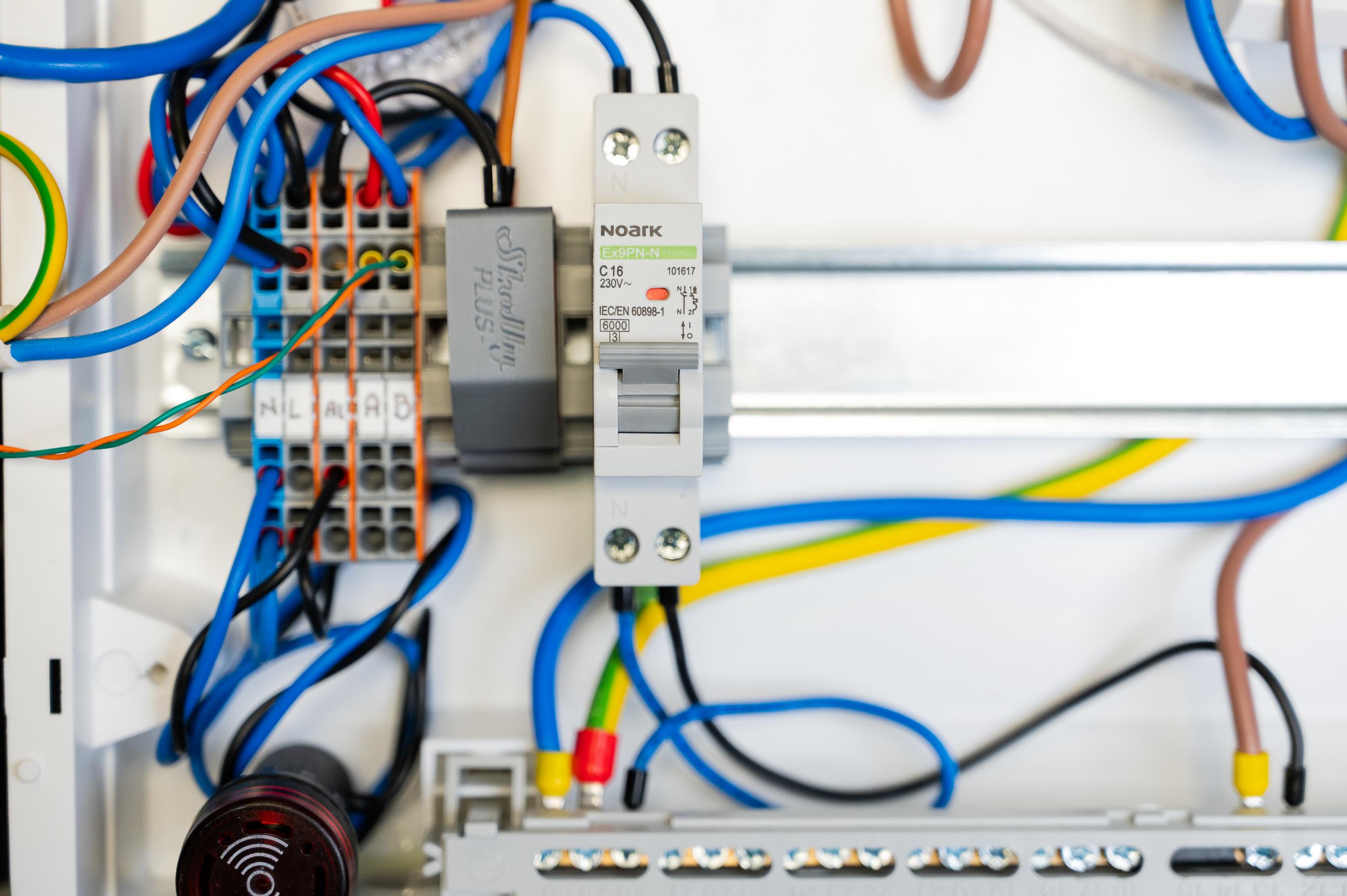

N potential terminal, Live potential terminal, Alarm output terminal, RS485 A terminal, RS485 B terminal Shelly 1PM Gen4 alarm controller, CB self needs

The ATS integrates grid supply, inverter AC output, and household load distribution. It automatically switches to inverter power during grid outage, protecting electronics and maintaining operational continuity.

There are other ways an inverter to be integrated into a house electricity distribution. This design was chosen as to allow maximum flexibility for maintenance of the system and was targeting an off-grid with occasional on-grid without selling to the grid scenario.

Data Acquisition and Cloud Communication

The Shelly Pro EM-50 provides granular measurements of energy flow across single or multiple phases. With the RS485 Add-on, Modbus-RTU communication can be established for data acquisition.

Cloud integration allows for:

Real-time remote monitoring

Visualization dashboards

Notification workflows

Historical data logging

Virtual Component Dashboard

For displaying the data retrieved from the inverter a built in system for extending Shelly devices is user - virtual components.

The system produces nine key parameters useful for both monitoring and decision-making:

Solar generation power

Household consumption

Grid import

Grid export

Battery charge level

Battery charge/discharge rate

Inverter efficiency

PV voltage/current

Cost per kWh (dynamic)

These values are visualized within a unified dashboard for daily operations.

Data Acquisition Script via Modbus-RTU

The Shelly Pro RS485 Add-on streams data from the inverter/battery using the Modbus-RTU protocol. A custom script polls the device at defined intervals and publishes results to the cloud.

Script responsibilities include:

Register mapping

Value parsing and scaling

Error handling

Data caching and pushing to cloud storage

This script enables real-time feedback loops for load-control automation.

Embedded Data Acquisition Script

The system relies on an embedded JavaScript application running on the Shelly Pro platform to communicate with the inverter and collect performance data in real time. The script retrieves values from Modbus registers, scales them appropriately, and publishes them as virtual components, enabling dashboards and automatons to consume structured information.

Disclaimer the script it tested and works properly on 1.8.99-dev148102 firmware revision.

/*

Shelly Europe Ltd. - Integrations Team

This example is dedicated for communication over MODBUS-RTU with a Deye solar inverter.

ENTITIES-based version + Virtual Components.

*/

const INVERTER_MODBUS_SERVER_ID = 1;

// Get a MODBUS-RTU endpoint: ID 1, baud rate 9600, 8 data bits, No parity, 1 stop bit.

const MODBUS_ENDPOINT = ModbusController.get(INVERTER_MODBUS_SERVER_ID, {

baud: 9600,

mode: "8N1",

pause_ms: 2000

});

// ENTITIES table describing all parameters + mapping to virtual components

const ENTITIES = [{

name: "Total Power",

units: "W",

reg: {

addr: 175,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "i16",

bo: ModbusController.BE,

wo: ModbusController.BE

},

scale: 1,

rights: "R",

vcId: "number:200",

handle: null,

vcHandle: null

},

{

name: "Battery Power",

units: "W",

reg: {

addr: 190,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "i16",

bo: ModbusController.BE,

wo: ModbusController.BE

},

scale: 1,

rights: "R",

vcId: "number:201",

handle: null,

vcHandle: null

},

{

name: "PV1 Power",

units: "W",

reg: {

addr: 186,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "u16",

bo: ModbusController.BE,

wo: ModbusController.BE

},

scale: 1,

rights: "R",

vcId: "number:202",

handle: null,

vcHandle: null

},

{

name: "Total Grid Power",

units: "W",

reg: {

addr: 169,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "i16",

bo: ModbusController.BE,

wo: ModbusController.BE

},

scale: 10,

rights: "R",

vcId: "number:203",

handle: null,

vcHandle: null

},

{

name: "Battery SOC",

units: "%",

reg: {

addr: 184,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "u16",

bo: ModbusController.BE,

wo: ModbusController.BE,

poll_int: 10000

},

scale: 1,

rights: "R",

vcId: "number:204",

handle: null,

vcHandle: null

},

{

name: "PV1 Voltage",

units: "V",

reg: {

addr: 109,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "u16",

bo: ModbusController.BE,

wo: ModbusController.BE

},

scale: 0.1,

rights: "R",

vcId: "number:205",

handle: null,

vcHandle: null

},

{

name: "Grid Voltage L1",

units: "V",

reg: {

addr: 150,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "u16",

bo: ModbusController.BE,

wo: ModbusController.BE,

poll_int: 10000

},

scale: 0.1,

rights: "R",

vcId: "number:206",

handle: null,

vcHandle: null

},

{

name: "Current L1",

units: "A",

reg: {

addr: 164,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "i16",

bo: ModbusController.BE,

wo: ModbusController.BE

},

scale: 0.01,

rights: "R",

vcId: "number:207",

handle: null,

vcHandle: null

},

{

name: "AC Frequency",

units: "Hz",

reg: {

addr: 192,

rtype: ModbusController.REGTYPE_HOLDING,

itype: "u16",

bo: ModbusController.BE,

wo: ModbusController.BE,

poll_int: 10000

},

scale: 0.01,

rights: "R",

vcId: "number:208",

handle: null,

vcHandle: null

},

];

function getScaledValue(ent) {

return ent.handle.getValue() * ent.scale;

}

function updateVc(ent) {

if (!ent.vcHandle) return;

const new_val = getScaledValue(ent);

const old_val = ent.vcHandle.getValue();

console.log(ent.name + ": " + old_val + " -> " + new_val + " [" + ent.units + "]");

ent.vcHandle.setValue(new_val);

return old_val;

}

function init() {

for (let i = 0; i < ENTITIES.length; i++) {

let ent = ENTITIES[i];

ent.handle = MODBUS_ENDPOINT.addEntity(ent.reg);

if (ent.vcId) {

ent.vcHandle = Virtual.getHandle(ent.vcId);

ent.handle.on("change", function (handle) {

updateVc(ent);

});

}

}

Timer.set(10000, false, function () {

for (let i = 0; i < ENTITIES.length; i++) {

updateVc(ENTITIES[i]);

}

});

}

// Run the application.

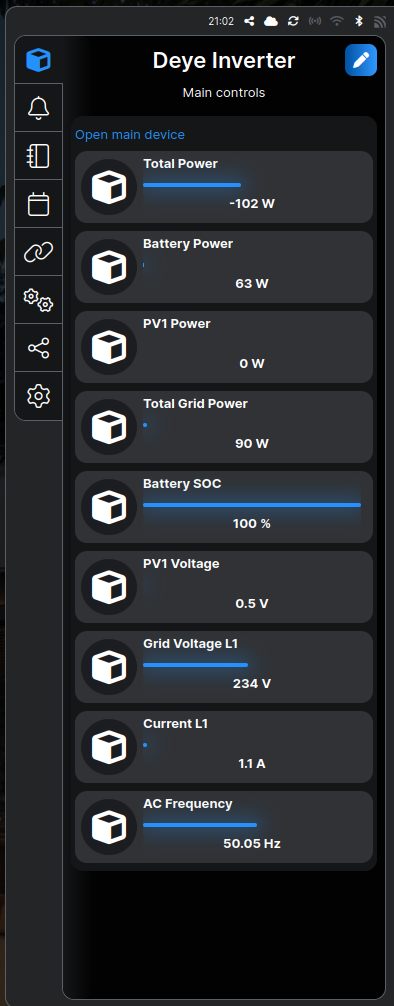

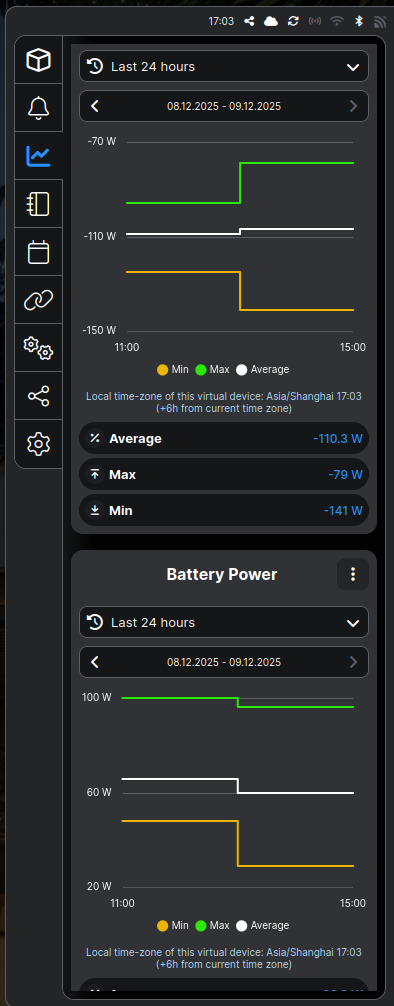

init();The result of acquisition results can be seen on the following screenshot.

Current values from the inverter

Values over time from the inverter

Energy Management Strategies

1. Storing Energy When the Price is Low

Time-of-use pricing enables strategic battery charging during off-peak energy cost windows. The system synchronizes with pricing data and schedules battery charge operations accordingly.

2. Selling Energy Back to the Grid at Peak Price

When energy prices spike, and battery storage is sufficient, the system exports energy back to the grid. This is controlled by inverter configuration and automated decision-making rules.

3. Determining Best Time to Charge EV

EV charging can be optimized using solar surplus or cheap night-time grid electricity. Decision factors include:

Real-time production/consumption

Battery state of charge

Grid pricing

Planned EV usage

Automation engine can switch charging sources or postpone charging based on cost-benefit logic.

Use Case: Household Energy Balancing

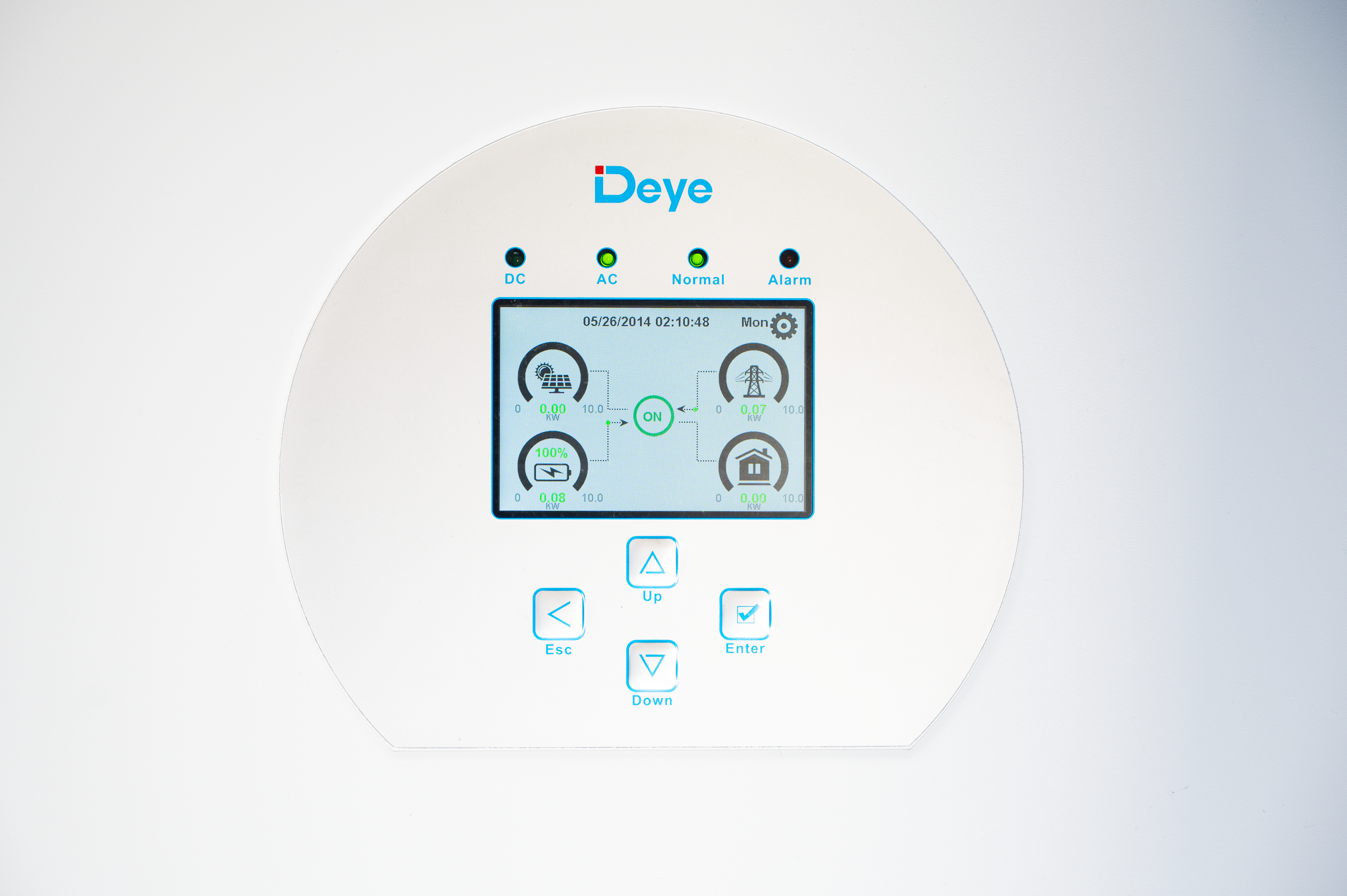

Inverter overview

Control panel of the inverter

A typical daily workflow:

Morning: Solar energy powers household loads; surplus begins charging battery

Afternoon: Excess power charges battery fully and exports to grid

Evening: Battery discharges to reduce grid imports at higher cost

Night: Battery charges from grid if night electricity is cheaper

Anytime: EV charging scheduled only when cost-efficient

Benefits

Reduced electricity cost

Revenue from grid export

Improved resilience and autonomy

Sustainable and transparent energy consumption

Scalable for future devices and smart home integration

Conclusion

This project demonstrates how to combine commercially available hardware and open-source tools to create a powerful energy optimization system. With real-time monitoring, automated decision-making, and intelligent storage management, households can actively participate in modern energy ecosystems while minimizing costs and maximizing sustainability.